Early adopters are leveraging track and trace capabilities in packaging to manage risk, improve operations and redefine how they connect with their consumers. Traceability plays a critical role for these early adopters as market volatility across all industries is being caused by supply and labor shortages. These trends and others are detailed in a new report from Smithers,

The Future of Track and Trace Packaging to 2027.

Stress on supply chains

It is an accepted fact that supply chain management is more complex than ever before. Manufactures across all sectors are experiencing the dual pressures of a volatile business environment and consumers’ increased expectations. The resulting stress on supply chains is unprecedented.

This perfect storm has placed a particular burden on many brands who also saw swift and irreversible changes in consumer purchasing behaviour caused by the global pandemic. This was coupled with an increase in counterfeit products across almost all product categories.

Industry has accepted that this is more than just a challenging moment in time, that disruption is the new normal. Now, it is imperative that manufacturers not only gain control of the resulting growing costs and exposure to risk, but also work to futureproof their supply chains.

State-of-the-art traceability

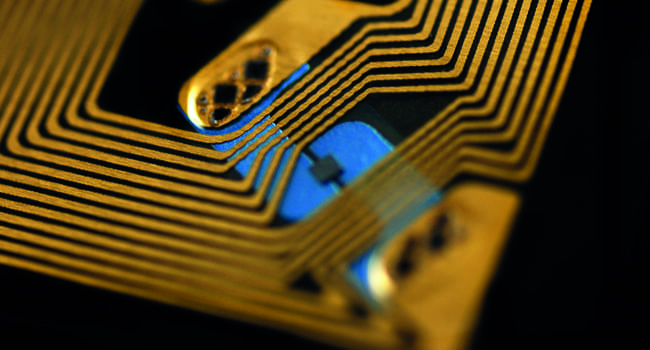

The most up-to-date traceability solutions enable manufactures to identify and capture data for key supply chain metrics that help build, measure and improve performance from manufacturing to marketplace. This proven technology exists for full end-to-end supply chain traceability.

These systems enable brands to track and record every product and transaction in their chain of custody. With traceability, they can instantly verify which products are where, which partners have them and how everything relates to each other. Traceability within food control systems helps manage food hazards, provide reliable product information and guarantee product authenticity and safety. Alongside, offering rich insight and data for improved consumer engagement and brand performance.

In the case of food recalls, traceability is essential. According to the Food and Agriculture Organization of the United Nations, all participants in modern supply chains are expected to have effective practices in place that allow for the rapid identification, location and withdrawal of food lots when problems are suspected or confirmed.

Addressing supply chain complexities

As supply chains become dramatically more complex, managing them will require a coordinated view of inputs, outputs, events, participants and processes. Traceability provides this visibility and enables a full range of actionable, real-time knowledge to help brands minimize threats and maximize operational excellence all the way through the system.

The fragmented nature of traditional supply chains with their functional silos is becoming a liability. Building a robust traceability program now provides the key data, partnerships and insight needed to transform supply chains into a competitive advantage.

Track and trace regulations

As track and trace regulations vary according to each country’s laws, all products must first be serialized so they’re easily identifiable within the supply chain. Some of the additional requirements could also include reporting of the data to the respective governments and regulating bodies, verification of the products where the product’s serialized number can be cross checked with other data to ensure it’s an authentic product.

Effective serialization is essential to avoid traceability complications. Serialization requirements also take into account the generation and format of the serialized numbers, aggregation of goods that can allow quick and easy scanning of products with their ‘parent vs child’ bundles, and guidelines to follow for packaging levels (primary, secondary and tertiary).

Freight security issues

Global supply chains continued to face significant security, continuity, and resiliency threats due to the COVID-19 pandemic, although the total number of incidents fell compared to the previous year. The spike in thefts at storage facilities was linked to an increase in idle times due to significant port congestion throughout the year, with an associated rise in insider theft, exacerbated by fraud and cybersecurity issues related to the use of digital connections between companies and transporters.

In North America the prevalence of port congestion and railhead delays was seen as a crucial factor facilitating thefts, while idle times in European locations also augmented theft and stowaway risk. Hijackings accounted for 26 per cent of cargo thefts in 2021, down from 30 per cent in 2020, with thefts from facilities at 25 per cent versus 24 per cent in the previous year and another 7 per cent of incidents linked to employee theft.

The products most frequently involved in global cargo thefts overall last year, included agricultural produce (12 per cent), food and beverage (14 per cent), construction materials (9 per cent) and electronics (10 per cent).

To download a brochure on The Future of Track and Trace Packaging to 2027, visithttps://www.smithers.com/services/market-reports/packaging/the-future-of-track-and-trace-in-packaging-to-2027