As a process suited to automated mass production, injection moulding is used globally for various plastic components globally. Understanding the materials, processes and set-up are thus key to its success.

Poor processing has been a significant factor in at least 40% of all product failures.

With many plastic products, a vast amount of time and resources go into the design and development phase to ensure that the product will meet its requirements and perform for its expected life. However all of this effort can be wasted when the product moves to the manufacturing stage.

From Smithers' experience, poor processing has been a significant factor in at least 40% of all product failures. This may cause immediate problems with components that are identified at an early stage, before they are released on the market. In the worst case the potential for failure remains unseen and occurs after a period of time and during service. It may be that the component is of low value and is simply discarded by the consumer when it fails. However, for high value and safety critical components the potential costs of failure can be very large in terms of recalls and loss of market share.

Processing and material behavior

Unfortunately, with injection moulding there is a distinct lack of understanding surrounding the effects of processing on material behavior. The fundamental behavior of thermoplastics is commonly overlooked due to this lack of knowledge. Simply passing the manufacturing of a component over to a moulder can be a recipe for disaster. In some cases corners are cut to increase profitability, other times the moulder may be inexperienced with the material and not have the required equipment. However, with some basic knowledge and independent assistance a more robust product can be manufactured.

Drying of granules prior to moulding often seems unnecessary, but excess moisture will create steam within the melt leading to voids or silver streaking. For some polymers the effects of moisture during moulding is far more serious as hydrolytic degradation occurs, resulting in a brittle moulding. In the case of hydrolytically sensitive polymers the drying regime recommended by material suppliers should be adhered to e.g. using desiccant or vacuum driers.

Excessive heating of a polymer melt increases the rate of thermal degradation, which again will lead to a brittle moulding. Wrong machine sizing can give an over-long residence time in the barrel, stabilisers within the polymer are consumed and the polymer degrades When a moulding appears difficult to fill due to a requirement for high pressure, many fall into the common trap of increasing temperatures to reduce the melt viscosity and injecting more slowly. Consequently the part now appears easier to fill but the polymer had degraded. The viscosity of a polymer melt is more reactive to shear than it is to temperature. Therefore, a quicker fill rate is more effective for filling and packing the cavity.

Cycle times will always be shortened to increase productivity. Cooling off the polymer melt quickly is one way to achieve this. It is also an easy way to achieve dimensionally accurate parts, at least for a short period of time after de-moulding. Yet, thermoplastics do not like to be rushed and prefer to be cooled at their own rate. Non-uniform cooling rates lead to differential shrinkage which in turn can lead to dimensional inaccuracies or high residual stress. If the mould temperature is low and the gate size small then the gate will freeze-off very quickly leaving the melt in the cavity isolated and free to shrink. If this is the case and the moulding cycle has a long holding phase at high pressure, all that will be achieve is a nicely packed out runner and a lot of wasted energy.

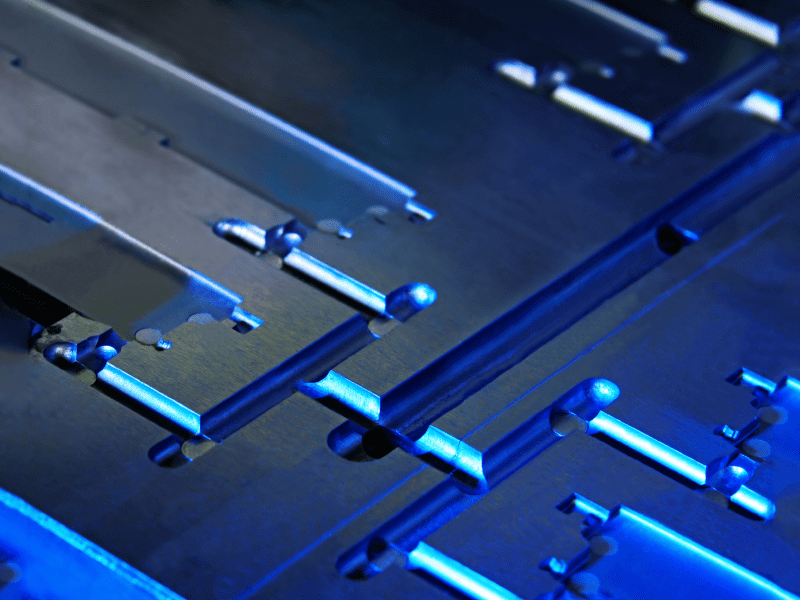

Tool configurations can also introduce a wide variety of features which can have a dramatic effect on part performance. The effect of gate location on the ability to fill parts and weld line locations are often all that is considered. Gate sizing has a big influence on the shear rate of the polymer melt and its resulting viscosity. The best way to evaluate the effect of gate size and location is by undertaking injection moulding simulation. By doing this the correct configuration can be determined before any metal is cut and minimising the trial and error of mould tool commissioning. For fibre reinforced engineering materials the location of the gate is critical in terms of the orientation of fibres. Changes in geometry and wall thickness disrupt the shear in the polymer melt and fibres tend to align only in the direction of high shear stress. As a result fibres may not be aligned in the direction required for maximum strength and shrinkage may not be as expected.

Overall, by being considerate to the behavior of a thermoplastic during injection moulding it is possible to produce very high quality and durable components for demanding applications. This can be achieved through the use of moulding simulations, effective specification sand quality checks and independent audits of the process. In the majority of cases the applications are not so demanding that it is possible to get away with poor quality mouldings. The downside can be that the optimally moulded component may cost marginally more to produce. But this may be a cost worth bearing in comparison with the total cost of product failure due to shortcomings in the moulding process.

Find out more about the polymer physical testing services we offer.