Mechanical shock is defined as a sudden acceleration or impact. In the real world, this translates to the jolt from a semitruck hooking up to a trailer or backing into a loading dock, getting hit by an object or sharp burst of air, or even just dropping something on the floor.

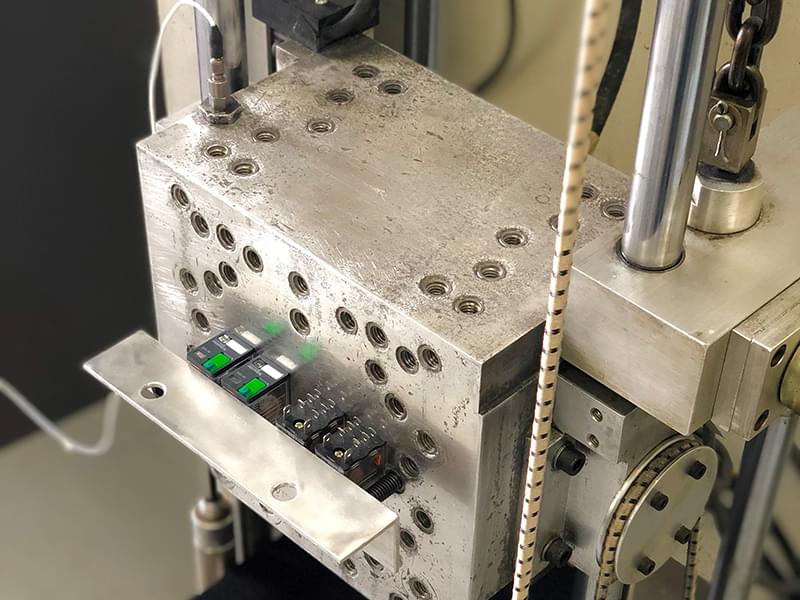

Mechanical shock testing is a protection against common risk associated with impact of all kinds and can assess how your product holds up against these and any other impacts they may encounter in their service environment.

That service environment is going to look different for every product. Thankfully, our lab can produce shock conditions that recreate the everyday environments of a lot of different products. Here are just a few interesting ones:

1. Electronics

Remember how frustrating it was to go for a run with your portable CD player, only for it to skip with every step? Our technology is decidedly more bounce-proof than it was a few years back, but similar issues still exist with

modern electronics. Anything that can be jarred or disrupted by high impact can benefit from mechanical shock testing during the development phase. This can include

vehicle electronics, heavy duty field equipment, and personal devices (because we’ve all dropped our phones at least once).

2. Safety equipment

Helmets, plexiglass and tempered glass products, even the safety glasses our engineers wear in the lab: Any product that is literally designed to protect you from impact should be subjected to mechanical shock testing.

3. Food

A bag of chips that’s 90% air or a half-full box of cereal can feel like a small tragedy, for the customer as well as the manufacturer fielding their frustrated calls. Mechanical shock and low frequency

vibration testing can measure how much jostling a flaked food product can handle before breaking and settling. It’s also a good place to start when you need to assess the fragility of other food products, such as portable snacks and pastries.

Michael Kuebler, our technical director of distribution testing, shares more about food settling in this Q&A.

--

Mechanical shock testing can help you determine whether your product meets regulatory requirements for safety as well as the highest level of impact it can handle. Investing in this type of testing can help you reduce product damage and safety loss, improve product performance, and, most importantly, provide a layer of safety measures for the consumer.

To learn more about mechanical shock testing, get in touch with Christine Bythewood at 330-762-7441 or cbythewood@smithers.com.