Automotive

Our automotive clients range from original equipment manufacturers (OEM's) to Tier 1 and 2 system and component suppliers and materials producers. Smithers also supports key suppliers in the supply chain to many of the leading North American, European and Asian car manufacturers.

Automotive component testing and product development services

Since 1925, Smithers has had extensive experience in designing and developing test protocols for automotive applications. Our technical support services are world leading and include failure diagnosis, design and process optimization and material analysis.

With extensive knowledge of rubber, polymer and plastic materials, Smithers experts can offer consultative insight – supported by materials analysis, product testing and transit simulation testing – to aid in your vehicle development efforts. Our testing services cover a wide range of performance evaluations on rubber, plastics, sealants, various vehicle components, tires and wheels.

Globally, we operate multiple ISO 17025 accredited automotive product test facilities, chemical and material analysis laboratories as well as facilities dedicated to distribution package testing.

Electric Vehicles

Electric Vehicles

Electric Vehicles

The experts at Smithers can support many stages of electric vehicle technology development on a global basis.

Fittings and Couplings

Fittings and Couplings

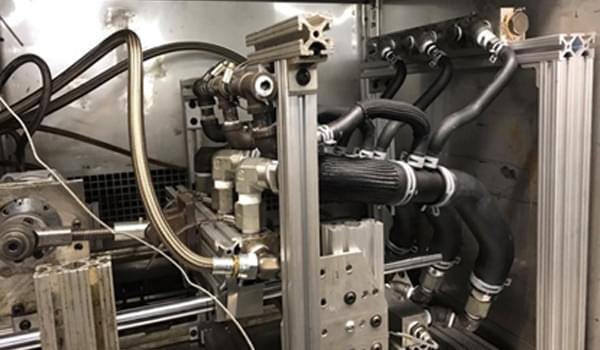

Designed to securely connect two or more pieces of tube or piping, fittings and couplings are a crucial part of complex fluid transfer systems.

Rubber Seals, O-Rings, and Gasket Testing

Rubber Seals, O-Rings, and Gasket Testing

While they differ in several ways, rubber seals, o-rings, and gaskets all serve the same basic function: To join two parts of a machine or engine by filling and sealing the space between them.

Tire Pressure Monitoring Systems

Tire Pressure Monitoring Systems

Designed to alert the driver when their tires are underinflated, tire pressure monitoring systems (TPMS) are crucial for improving driver safety, fuel economy, and tire durability.

.jpg?ext=.jpg)